top of page

Music Box

We have no words to express our gratitude towards Pinchas and Dudi from Bezalel's workshop, Yarden from Beit Hansen's, and Avi from the architecture department. We couldn't have done anything without their help and kindness.

Thank you so much.

Based on this tutorial

The Musical Mechanics

Box and Drum

Rhino for CNC

We made two drum options:

1. Horizontal layers

2. Vertical layers

Since we didn't know if the robotic arm could drill holes so close together without splitting the MDF, we tried to come up with various ways to construct the drum.

Laser cutting - Bezalel

AutoCAD for CNC

CNC - Beit Hansen

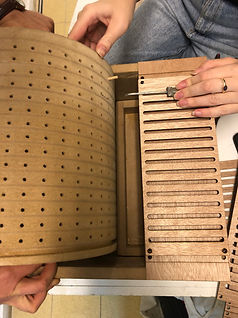

Drum

Box

Assembly

The metal we cut didn't make any sound. We think it's because of the type (tin) and/or because we got thin sheets of 1 mm (expense limitations) and then we couldn't tighten the parts correctly.

Changing the plate to wood

Final Thoughts:

Vertical layers

Horizontal layers

First try didn't work and we didn't have time to try again

Gluing the layers and preparing for the robot in Bezalel

Robot in Bezalel

.jpeg)

Assembly

Tuning

The drum isn't completely symmetrical, and was too close to the plate. modifications to the box had to be done.

.jpeg)

.jpeg)

.jpeg)

Many last minutes modifications

Assembly and tuning

Punch Cards

AutoCAD for laser

Final Thoughts:

We should have given more thought to the material we used, the MDF presented a lot of problems along the way, and perhaps purchasing a different kind of wood would have been easier.

When basing work on an online tutorial, read it all through properly first!!! Building a smaller scale model would have helped to understand the mechanical system better, before we spent the money on the real deal.

The acoustical and musical aspect was a lot more complicated than we thought. We would have benefitted from more time from trial and error to learn these aspects better.

bottom of page